- RotaFlow spreading system.

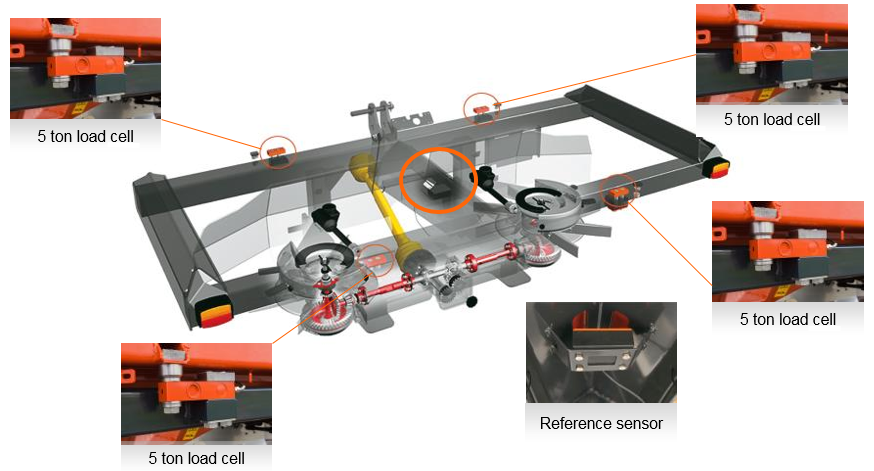

- Fully automatic weighing system with unique reference sensor.

- The 2 metre sections (max. 24 sections) can be switched inside-out and outside-in to keep overlaps to the minimum .

- ISOBUS 11783 compatible for easy plug and play.

- Combination with IsoMatch GEOcontrol.

- Automatic start/stop with GPS on headlands possible.

- When running IsoMatch GEOcontrol in addition to GEOspread you can set the DSX-W GEOspread more accurately. The working width will be automatically adjusted to suit the overlap and coverage using a GPS positioning system. For example, when driving in a wedge or irregular shaped field, GEOspread will start to decrease the working width step by step. GEOspread is using the section control function of the IsoMatch Tellus software which is in the IsoMatch Tellus terminal. The spreader working width is divided into a minimum of 2 metre sections (max. 24 sections on DSX-W GEOspread and max). Not only the spreading width is adjusted, the application rate (kg/min) is also adjusted automatically to match the revised spreading width. This unique combination of working width and application rate adjustment makes the GEOspread system extremely accurate, with minimum influence on the spread pattern coefficient of variation.

- Quick and accurate spreading, due to the actuators being directly connected to the discharge point. No linkages.

- Stable disc RPM in combination with discharge point adjustment maintains the spreading pattern (coefficient of variation).

- Easy operation; no need to step off the tractor to adjust the working width.

- 100% ISOBUS compatible for easy operation.

- Automatic start/stop with GPS on headlands possible.

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continuous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- The compact FlowPilot ‘dashboard’ gives you considerably simplified accurate setting and adjustment of application rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

- The development department of Kubotas spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirement.

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The RotaFlow 6 step checklist helps you to ensure consistent accuracy in all field conditions:

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

4. Select spreading table

5. Select field settings

6. Adjust FlowPilot system

- Kubota offers the TrimFlow system. The TrimFlow can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI), indicates which border spreading device is active.