- Stable parallelogram.

- All parallelogram pivot points with maintenance-free bonded bushes.

- All press wheels with maintenance free ball bearings.

- Chill cast coulters with quick release clamping to the coulter housing.

- Module sowing units: The basic element always remains the same and the equipment can be varied according to individual requirements.

- Easy exchange of various coulters and press wheels depending on seed type and soil conditions.

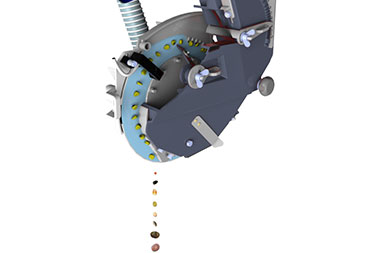

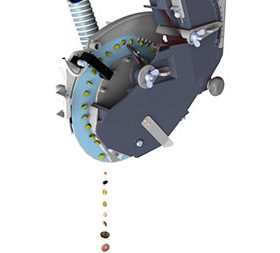

- Patented seeding heart without seals.

- ISOBUS intelligence.

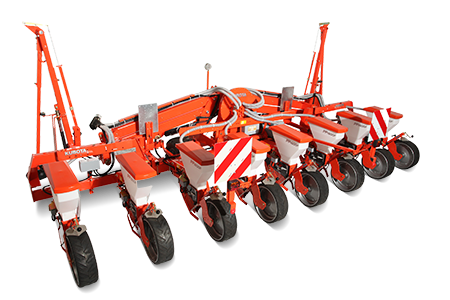

- Suitable for all farm sizes, the frame of the Pneumatic Planter is available in working width from 3 to 12m, with telescopic, rigid, trailed and folding toolbar.

- The sowing units – like the whole machine – are modular in design.

- The basic element always remains the same and the equipment can be varied according to individual requirements.

- The press wheels run on maintenance free ball bearings. The sowing depth can be infinitely adjusted by means of a screw jack. A scale ensures even depth adjustment over all rows.

- The sowing coulters are designed with a high attachment point. This enables them to work deeply when sowing beans or on dry soil, without the housing being subject to wear.

- Precise depth control is achieved via the tandem design of the sowing units for beet.

- Standard sowing unit for conventional seeding in prepared conditions: maize coulter and Farmflex depth wheel 370mm (500mm optional), spring-loaded coverer and lifting device as standard.

- PP sowing unit: elements for mulch and conventional seeding.

- Seeding heart without seals.

- The patented seeding heart by Kubota has reduced maintenance costs to a minimum.

- No friction, no wear, low drive torque, minimum maintenance: The seed disc rotates in the seeding heart together with the vacuum chamber. This seeding drum is connected to the vacuum fan via a hollow shaft.

- This seed heart principal results in no loss of vacuum, and therefore a low vacuum requirement.

- e-drive II – complete control and monitoring of the machine from the tractor cab in accordance with ISOBUS standard.

- With e-drive II, each sowing unit is driven individually via an electric motor.

- The low-maintenance drive is connected directly to the seeding heart via a toothed belt in an encapsulated dust proof housing.

- This enable an extremely compact design and smooth drive characteristics with low current consumption.

- All the data is entered and read out via an ISOBUS terminal like IsoMatch Tellus or Tellus GO.

- The sowing distances are infinitely adjustable and can be changed during sowing.

- All the sowing units can be switched off individually.

- In conjunction with “close row” sowing widths of 37.5cm a further benefit of the e-drive II comes into play: Individual tramline switching. Tramlines can be set up for any spray width.

- The e-drive II features complete electronic monitoring of all machine functions including seed monitoring via an opto sensor.