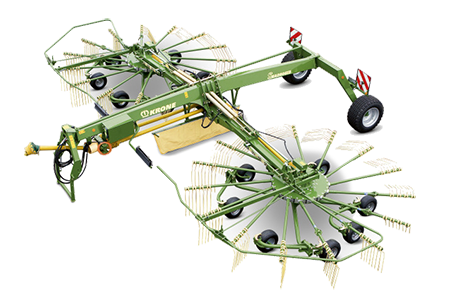

- Krone rakes excel with their well shaped windrow formation. This ensures that the following harvesting equipment can increase forward speed and productivity as well as produce the perfect product for example well shaped square bales or even flow of crop in the forager.

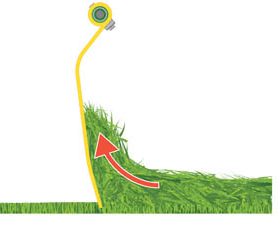

- There are two secrets in this machine. One is behind Krone’s steep cam track angle. This allows the tine arms to pivot very quickly which results in the tines to lift up fast to form an even filled square windrow. The second is the faster speed of the front two rotors over the rear rotors for no roping effect.

- The standard centre swath curtain can be used when forming the windrow.

- Customers tell us our rakes are the cleanest in the field. Our tines are pointing forwards which means when the tine loads up the distance to the ground decreases, to put all that valuable crop into the windrow rather than leaving it behind.

- The new lift tine is even more forward facing to be exact about 100mm up the tine rod. This simple improvement results in the crop running up the tine rod, so that less material is dragging along the bottom of the tines which reduces crop losses, crop contamination and allows operators to finally use rotary rakes at faster forward speeds.

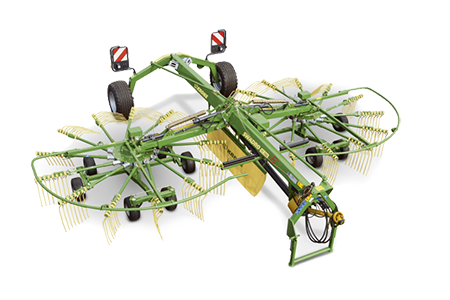

- Krone tines are strong using 3 coils and 10.5mm rods. 4 double tines per rotor are standard and the Swadro 2000 offers 13 tine arms per rotor on the two front and 15 tine arms on the rear rotor.

- Swadro 2000 offers electric rotor height adjustment from the cabin with height shown on the LCD screen. New on this Plus model is the ability to adjust one rotor followed by a push of a button so that all other three rotors adjust to the same tine height.

- The cam track inside of our rotor is dry and does not require any lubrication. We offer 3 years warranty for the cam track for absolute peace of mind and to be honest we never had a warranty claim yet.

- All tine arms run in large sealed bearings. This means there is no daily greasing of tine arm bushes. The only grease intervals are on the PTO shaft and for the rotor wheel axles, so simplicity increases your productivity so you can be raking in the field rather than greasing.

- If you have bent a tine arm or later on in the life of the rake replace a roller bearing of the cam follower, just simply remove the whole tine arm assembly by loosening a couple of bolts. Compare this to disassembling the whole rotor housing to get to these items. The Krone design gets you going much quicker.

- Knowing that rotary rakes do not require a lot of tractor PTO horsepower, the engineers have reduced the PTO speed requirement to 350rpm to 450rpm. This will save you fuel and reduces noise, as your tractor runs slower compared to 540PTO speed.

- Single rotor lift out is a standard feature for all Australian rakes. This allows you to lift either side of the rake or individual rotors even.

- All Swadro rakes are under 4m transport height.

- The Krone Jet Effect, means the rotor always lifts at the front first and sits down at the rear first when lowering the rotor, just like an airplane takes off and lands. This results in the tines not digging into the ground when lifting the rotors which reduces wear, strain on the drive train and crop contamination.

- The largest tyres are used for the transport wheels and under the rotors. The rake comes with the CCI200 Isobus colour touchscreen monitor.

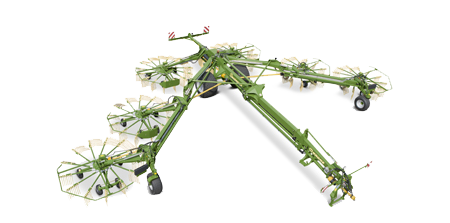

- Standard for the Swadro 2000 is hydraulic width and swath width adjustment. This can happen independently from each other so that even though raking at the smallest work widths of 10m the windrow widths can still be altered wide for example. The high clearance frame and high rotor lift out allow the rakes to travel over massive windrows without disturbing them.